Snowy 2.0 Hydraulic Analysis

Project: Snowy 2.0 Hydraulic Analysis

Location: Cooma, NSW

Duration: 6 Months

McDowall Affleck was engaged by Future Generation Joint Venture (FGJV) as part of the Snowy 2.0 pumped-hydro project to complete a hydraulic analysis of the temporary industrial water supply and the dewatering system in the tunnel network.

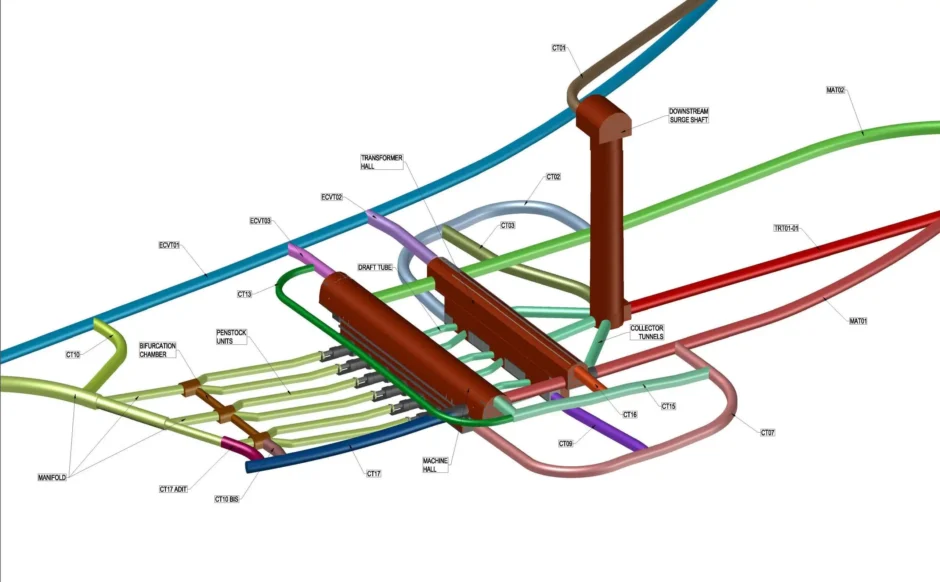

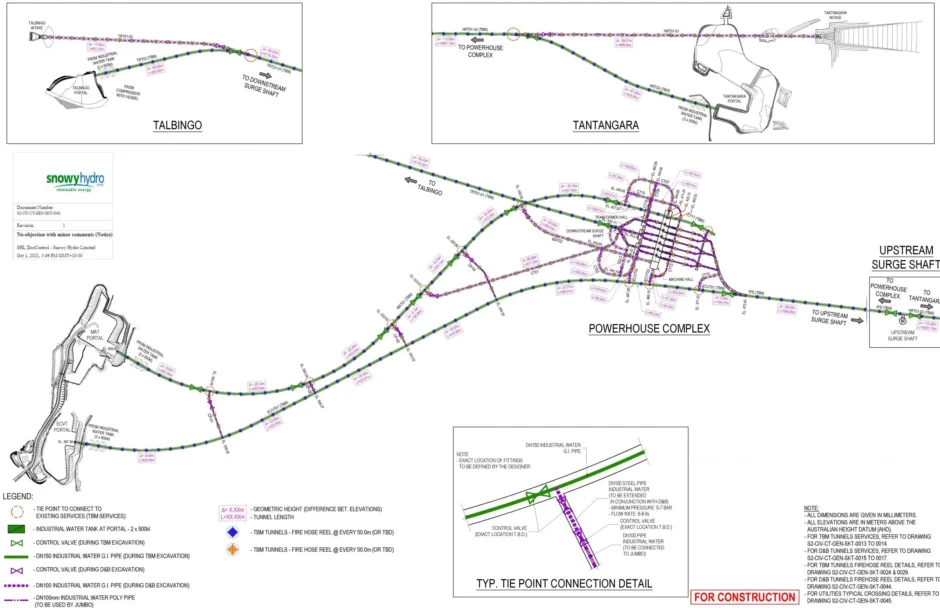

The tunnel network includes the Main Access Tunnel (MAT01) and the Emergency, Cable, Ventilation Tunnel (ECVT01), along with the various interconnecting tunnels. These two main tunnels connect the water tanks at the tunnel portals with the powerhouse complex.

The industrial water supply conveys water from the portals via 200mm diameter pipework to drills, which will be drilling and blasting tunnels around the powerhouse complex. The dewatering system conveys the groundwater and muddy water left over from drilling and blasting operations to the portals via 250mm diameter pipework for treatment and reuse.

As part of the analysis, we modelled the complete piping network throughout the tunnels, and conducted the hydraulic modelling in PIPES software. We assessed the industrial water supply and dewatering networks for several project stages, where different drilling fronts were expected to be in operation at the same time.

We identified some deficiencies in the networks, and proposed solutions to overcome these issues, such as incorporating larger storage tanks or additional pumps at strategic locations. We found that the hydraulics were complex due to the operation of multiple pumps at different elevations and variable flow rates. Turning on and off large pumps in the networks had a significant impact on the hydraulic gradeline and the performance of the smaller pumps.

McDowall Affleck worked closely with the team at FGJV to provide practical solutions based on the availability of pumps and equipment on site. This ensured the piping networks would meet the requirements through all stages of the project.